| Topic Review |

fola

|

posted on 6-1-2020 at 20:18 |

interested...

| Quote: | Originally posted by tamar

Ah I see, you mean this Bentley

Well as you can see, its already been modelled in 3D, yours to acquire @ $129

It will take about another $200 - $400 for a 3d modeler to convert the model into a printable file(s).

Another $100 for high res prints of the masters for the to be vacformed clear parts.

So you're looking at ≠ $600 startup costs which do not include the manual preparation of the printed masters for the vac formed parts.

Print costs for such a body would range between $40 -$60 per item, vacformed parts would cost between $5 -$ 8 per item ex shipping.

So for a limited 3dp production of the 2018 Bentley you would need to sell a 100 cars @ ≠ $85 to break even.

Could be done on a crowd funding base...wanna put your money where your mouth is?  |

|

Grunz

|

posted on 11-9-2018 at 18:15 |

I do not have the time to set up all of that, but if someone would start a crowd funding project I would surely chip in.

Actually, some of the manufacturers should look into the crowd-funding approach: they could ask for a pre-production target sale to be reached for the

project to be viable.

|

tamar

|

posted on 11-9-2018 at 12:49 |

Ah I see, you mean this Bentley

Well as you can see, its already been modelled in 3D, yours to acquire @ $129

It will take about another $200 - $400 for a 3d modeler to convert the model into a printable file(s).

Another $100 for high res prints of the masters for the to be vacformed clear parts.

So you're looking at ≠ $600 startup costs which do not include the manual preparation of the printed masters for the vac formed parts.

Print costs for such a body would range between $40 -$60 per item, vacformed parts would cost between $5 -$ 8 per item ex shipping.

So for a limited 3dp production of the 2018 Bentley you would need to sell a 100 cars @ ≠ $85 to break even.

Could be done on a crowd funding base...wanna put your money where your mouth is?

|

Grunz

|

posted on 11-9-2018 at 01:56 |

That evotech shop has a lot of interesting stuff. Which other lightweight parts did you order for the lambo?

That Conti looks very nice and I am sure that the prospeed chassis will make the car very competitive. As for the Ver 2 (or Mark II) I was referring

to the new 2018 Conti. Still no one is making this car.

But given the pace at which Scaleauto is updating its GT3 line up, I would not be surprise to see the new Conti being announced by the end of 2019.

|

tamar

|

posted on 11-9-2018 at 00:31 |

Hello Gio

I ordered the inserts and some of the vacformed lightweight stuff for the Huracan from evotecshop.com

I guess Tom will be reading this post with the same interest (as he's building the R8 as well)

Version 2 of the Scalex Bentley will have to wait till after Le Mans 2019. I would like to use an updated version of the ProSpeed Bentley chassis.

I'll most likely strip the M-Sport body and hope to play a bit with the hasegawa mirror foil to do the chrome roof of the Japanese Conti

|

Grunz

|

posted on 10-9-2018 at 21:51 |

Those Sideways rims are very good. But even on the Huracan I had to do a lot of work to trim them down and fit properly.

I have three huracan white kits. One of the insert sets has found its way into my Scaleauto R8.

I have been looking for getting just the inserts but I have not found them.

Where did you order them from?

The MF Conti looks really good. I am looking forward to his younger brother (the Version 2).

|

tamar

|

posted on 10-9-2018 at 20:20 |

Hello Gio

Yeah hit myself on the head when I realized that the Scalex chassis had been binned. Here's what happend: remember me moving house about 1 1/2 year

ago? Packed a 100+ boxes for the ladies in 3 weeks... but ended up packing all my stuff on the night and even the day the movers came.

I distinctly remember my daughter holding up a box with parts asking me what to do with it..and after a quick glance I said "dump it in the bin". I

was a bit stressed..to say the least.

Old Shoes

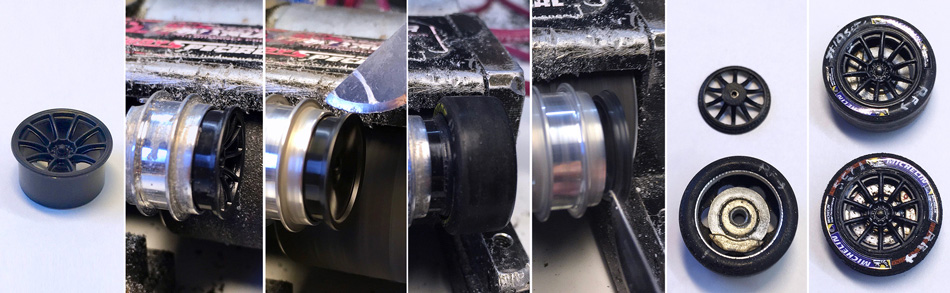

Good thing you mentioned the Bentley wheels, it reminded me of a small task that had been lurking on my work bench for almost a year. The original

Scalex wheels are pretty good, but as you mentioned hard to mill down and turn them into inserts.

You know I have a wheel fetish, so I had the correct 11 spoke inserts drawn in 3d and cast by Rendel Design. Although the cast were very good and

clean..the wheels somehow lacked "body" and did not curve inward as much as the original. But as they say: in the land of the blind.....

Then Sideways released the first pictures of their Lamborghini Huracan and I immediately knew I had to have those wheels no matter that they "only"

have 10 spokes... Man did they look good. So I ordered the white kit and when they became available as a spare part...4 bags of inserts.

Trimming the Sideways inserts

As you know (because you have the Huracan) Sideways used the same construction method for their inserts as they did with the Gr 5 cars. True to scale,

but the outer flange of the insert is mounted on the outside of the rim. Note a problem if you can glue & true your own tyres, but it does cause a

problem when you need to fit them to the Scaleauto Procomp3 wheels. So here's what I did...

From L to R:1 Original "Full sleeve" Sideways insert. 2 Mount the sideways rear wheel to your Tyre truer. Mount the insert half way,

don't push it in too far or you'll have a real hard time getting it out again. 3 Use low revs and a sharp knife to mill the outer flange

down. Take small steps at a time and..4... test fit the wheel you want the insert to fit in. 5 If the wheel fits use the knife to cut

trough the outer flange of the insert and then go in deeper to cut the axle sleeve. 6 You may still need to trim a bit of material from the

inside of your wheel to get a proper fit, and may have to sand down the rear face of the insert as well. 7 the finished wheels

New Shoes

She's got some battle scars, her antenna's are a bit bend, her chassis has some cracks....but with a new pair of sneakers the "old gall" still

looks "bad ass"..actually she looks better than ever...Now if only I could find the time to do those beaming foglight clusters under the grill

...this project might actually come to a finish.

p.s: I picked up a new Scalex Bentley at a bargain price when I ordered the M6, so I can now finish the Scalex Bentley as well....one day

|

Grunz

|

posted on 10-9-2018 at 05:32 |

Why did you bin the chassis!!!! You could even savage the wheels to make some nice rims.

I tried but failed...so I am using the BA inserts for mine.

|

tamar

|

posted on 10-9-2018 at 01:59 |

LOL Gio

I did the same on my Scalex Bentley, but I had already binned the original chassis..so ended up cutting the skirts from the 3DP chassis.

|

Grunz

|

posted on 6-9-2018 at 04:11 |

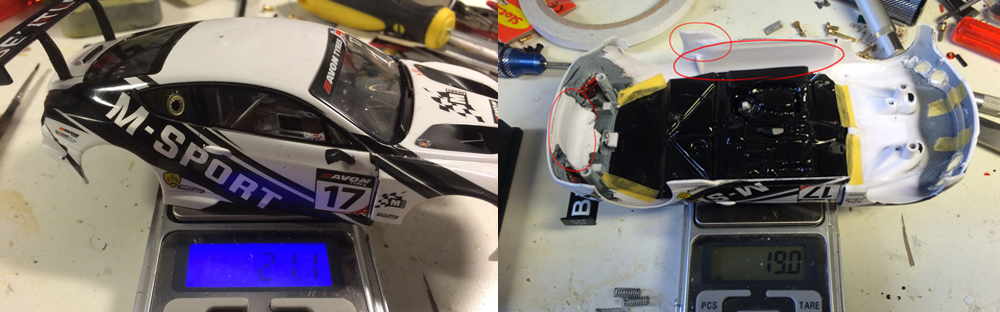

Here is an update on my scalex Bentley that I recommend in case you want to race this car in a more competitive form.

The main issue here is that the way the chassis and body were designed by scalex makes the side of the body "sits" on top of the chassis. In the

following I will try to explain what is the problem and how to solve it.

Below you can see a pic of the original chassis from slot.it. Looking that the side of the chassis, slot.it has replicated the same details as in the

scalex bentley chassis: basically the wall details on the front wheel wells and the skirts where the exhaust pipes come through are still there.

.jpg)

To promote body float and improve handling, we want to allow the body to freely move without hinging on the chassis.

So, first of all, I removed the details on the side of the 3D-printed chassis using a cutting disk and a dremel.

Here are the results:

.jpg)

Then I did the same operation on the original scalex chassis. By cutting the details carefully, I was able to glue them to the body.

Below you can see how I glued them to the side of the body adding some flat styrene pieces to provide more support:

.jpg)

.jpg)

.jpg)

The picture below shows how the sides of the body are now sitting "around" the chassis and not on top of it:

.jpg)

And finally, how she looks after 2 years of bashing her around:

.jpg)

After doing this operation the car handles much better and as a bonus it even looks better in my opinion (the details on the 3D printed chassis

didn't look that good).

|

Grunz

|

posted on 22-8-2018 at 14:36 |

Thanks Tamar. It is amazing how small details can make a model look more real.

As I said, nothing really major but I do love the way those front canard wings make the car looks more aggressive.

Thanks also for the fog light details. Again, this is another bit of details that change the look of the car (in IMO anyway).

|

tamar

|

posted on 22-8-2018 at 14:35 |

Looking good Gio.

I'll see what I can do for your missing fog light detail. I will draw them for the decalsheet I'm going to do for the TA71s Conti.

|

Grunz

|

posted on 22-8-2018 at 10:34 |

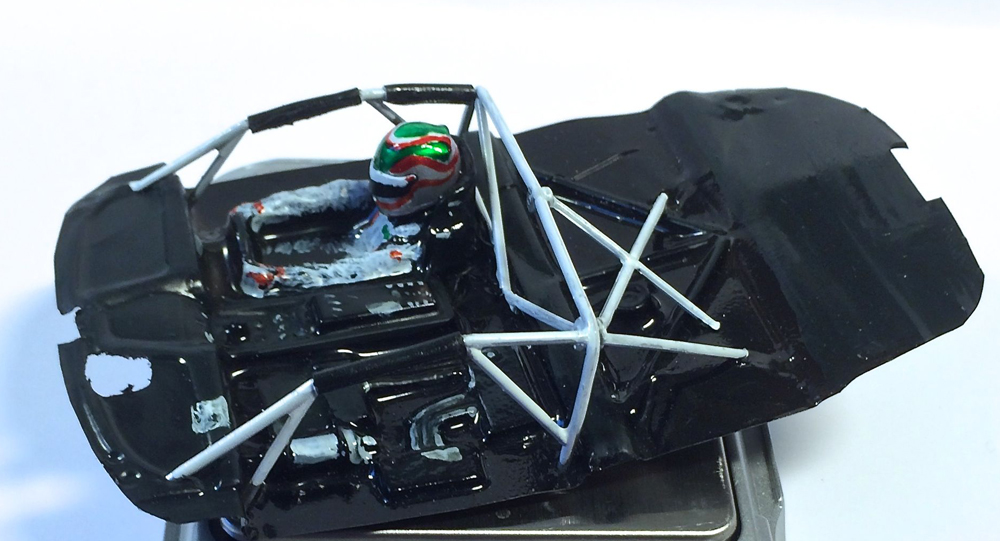

Yesterday I received the interiors from John Warren - AKA Munter.

Not only he embarked on this project in a very short notice finding some time from his busy schedule, but he did more than one tray and in different

trim as well.

Thanks John.

Looking at Tamar's interior, I wanted to achieve a similar level of details.

John's tray is very light to start with. Adding some of the details from the original scaley car, I managed to get to 1.56 gr.

I have added the rollcage, the pilot helmet, the top part of the seat with the head support, the fuel pipe on the rear of the pilot and a comm

cable.

.jpg)

.jpg)

.jpg)

.jpg)

Because I have cut the tray a bit too short, I had to put some black tape to extend the rear of the tray...This has added a bit of extra weight.

So the final weight of the car is a wooping 20.42 gr

.jpg)

And this how she looks on the setup block

.jpg)

|

Grunz

|

posted on 22-8-2018 at 10:30 |

Here is a bit of update on my Conti. First of all, last Saturday, after our DTM race, I raced it against 3 NSR porsches. The car was handling

beautifully in the corners. The porsches were a little faster on the straight just because they had a taller gearing (stock 31/13 vs the conti 27/11)

but didn't have any suspension kit as the conti. They are also a good 5gr lighter.

Anyway, during the weekend I have put a bit of details on the body work.

First the canards in the front. These are made from the extra material left from a lexan interior attached to the body via a piece of wire (a piece of

leg from the resistor I used for taming the rear lights).

I had to drill a small hole by using a very fine bit. I have also opened some vents below the grill and put more bits of lexan material to make look

like small radiator grills (it is not really so visible in the pic below).

I have now the opening for the fog lights but I miss the details inside it (the 3x3 matrix LED). Finally I have made a simple rope for pulling the car

in case of a crash.

.jpg)

Here is a pic of one side of the car

.jpg)

A bit more details below. I have painted the rims, opened some vents on the back, and opened the exhaust hole.

.jpg)

On the back I have also put the small ring for pulling the car

.jpg)

Nothing really fancy or at the same level as Tamar here. But if I can do it anyone else here should be able to add a bit more details to their

cars.

Next week I should receive my interior from John. I will do some of the detailing described by Tamar here.

|

Admin 1/32

|

posted on 21-8-2018 at 20:50 |

Hello Guys

I've copied this topic over from my posts on Slotforum as

A: my pictures are no longer visible there after SF moved to a google cloud platform (https - vs -http)

B: The methods described for the Bentley GT3 on how to get heavier slot car bodies closer (or on) the 19gr weight will apply to all GT3 cars build

under DiSCA rules.

There may be some missing links and posts in this thread, but the general message should be clear.

Here's a link to the original topic:link

With kind regards

Tamar

|

Tamar

|

posted on 22-6-2016 at 12:04 |

Hello Guys

@ Gio: That's the advantage of the "smaller" 1/32nd scale.. you can get away with "suggesting" detail rather than actually making them.

So thx for the compliment, but in the close up you can see that all I've done is highlight some of the detail with white primer, (gives that nice

semi gloss sheen)

and painted the dash and parcel shelf Tamiya Nato black (actually a very dark grey)

Used the stock Scalex helmet and roll cage, pimped the helmet with some flashes of red and green clear, painted the rollcage with wite primer.

@ Gary:I agree that's why I cut up some heat shrink tubes and wrapped them around the rollcage.

@ William: Vacformed parts are usually 0,1 -0,2 mm bigger as they're formed over a positive master.

This is not a problem for bigger parts like windows and interiors, but for light lenses you will have fitting issues.

Not to mention that cutting such small parts to shape can be a pain in the ass...ask me how I know.

Vac formed windows and light lenses are the items Gary mentioned as not allowed lightning suggestions.

As for the Bentley, the lamp lenses have moulded detail on both the outside and inside surfaces, so if you vacform those you'll loose all the nice

inside detail.

|

LMP

|

posted on 22-6-2016 at 10:22 |

The scope of these discussions sure have gone beyond a 'crash diet' to something more intensive, that's clear! The OP was intended as a quick and

easy 'most bang for the buck' in terms of effort. It also meets DiSCA GT3 spec, which several of the other lightening suggestions do not.

Fitting my interior (with cage), my Bentley comes in at 20.5g. I'm more than happy to leave it there.

It is worth remembering that there are some very 'heavy' lexan interiors out there. I have fitted one of Charlie Fitz's RHD interiors for 1/24

cars, and it's nowhere near as thick or as heavy as some of the vac-forms out there. I don't have the Slot.it part, maybe theirs is just as good.

Tamar - love the foam insulation around the cage - the cage alone was just not good enough

|

Grunz

|

posted on 21-6-2016 at 23:12 |

Hi Tamar

yes I noticed about the scale too ;-)

For the pod, I guess you mean the two extra anchor points on the side of the pod right? I was going to chop them as we usually do for our analog

racing on the SW pods.

The idea is that they impede side movement of the pod. But then I was that you are using grabscrews on them...I tried some grabscrew on mine but the

holes are too big.

So I went for two screw that are used for fixing the DPR chips on the chassis.

By the way, that interior of yours look awesome. I was planning to put the rollcage on my as well.

|

Tamar

|

posted on 21-6-2016 at 22:10 |

Hello John, Gio

Here are some pictures.

@ John

Yep, this thread is about a stock Scalex Bentley Continental...and what you can do to improve its handling.

As Gio mentioned these cars are build to Disca GT3 open specs, but even for those who run their Conti at home with the stock chassis and a ssd

chip...

Forget about the dremmeling and cutting out sections of the glass...spending £5 on a vacformed interior would be the best tune up money can buy.

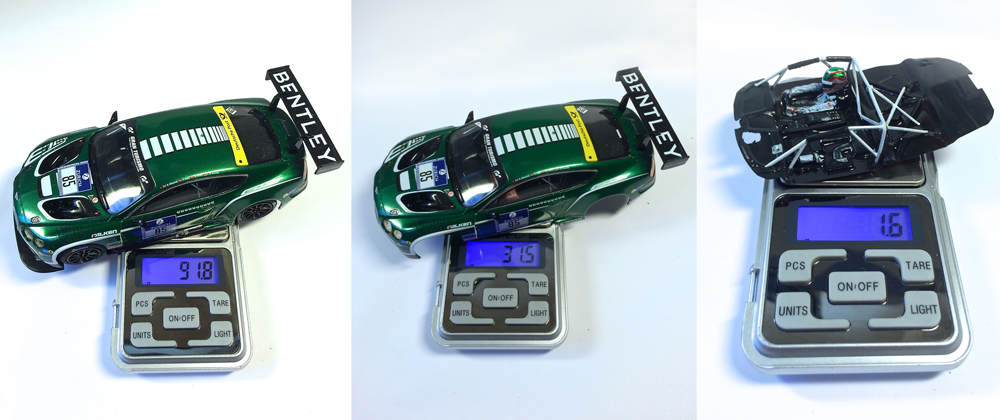

To the left the Stock Scalex Conti, 91,8 gr unchipped. Middle image stock body with full interior 31,5 gr. The reason why the Bentley is heavier after

the diet than stock is due to the engine swap (Long can motors are 8gr heavier than small can) and O2 bits and bytes (chip & hall sensor 4,2gr)

But most of that added wheigth is low down on the chassis.

@ Gio

Vac formed interior (MTR32) with Scalex rollcage and helmet, 1,6gr. Actually the rollcage is not required by the regs, but hey that extra 0,7 gr is

worth its weight as eye candy. Set of Scaleauto procomp3 wheels with inserts 3,4 gr. Cherry on you diet cake would be a slot.it PA01-54H hollow front

axle which would save you an other gram.

with kind regards

Tamar

p.s. @ Gio: I see that we're both using the same scale, I also saw that you have used the evo-6 pod...good!

Dont chop off the arms for the side suspension, I will post on that subject soon.

|

Grunz

|

posted on 21-6-2016 at 03:36 |

Yesterday I did another pass on the body of my conti and manged to shave off another gram.

I think that is good enough for me without making it too thin and fragile.

.jpg)

I have removed all the lead on the chassis and put in the suspension kit. This is what she weighs now:

.jpg)

I have ordered the BS motor and the wheels from Gary. I think that once I install the pro-comp wheels she should lose some more grams.

|

Tamar

|

posted on 17-6-2016 at 16:40 |

Hello Guys

Here's an update on how

to put your Scalex Conti on a Diet. As with all weight loss programs...its a case of shedding tiny bits of weight here and there. Here's an update on how

to put your Scalex Conti on a Diet. As with all weight loss programs...its a case of shedding tiny bits of weight here and there.

In the Disca

testing we like to take things step by step, so on the bottom left you see the weigth of my Conti with the steps taken as Gary described in his

earlier post.

Removed the centre glass section and the little bits. Gary's estimate of 21gr with a lightweight interior was spot on.

Not

bad for a 1st stage, but considering we'll be up against a lot of light BA bodies that will most likely need balast to achieve 19 gr. time for stage

2.

My preferred tools in such matters...the rounded #22 X-acto blade and these Dremel bits. The thing you want to avoid here is...heat.

In stage 2 there are no big lumps left to remove, so instead of whole grams, you'll have to look for area's where you can shave a few tenths.

Find five of those and you do have a gram less. Its as simple as that. You provide the elbow grease and sweat, she'll loose the pounds (or

grams in 1/32  " />) " />)

On the bottom right you can see where I found extra material

could be easilly removed. The area just in front of the rear wheel arches I wanted to thin anyway as here the chassis was rubbing against the body.

The door panels were a second area, these are the same as those super resistant Scalex bodies so take out your scalpels and scrape away.

Then

there's the back of the boot lid, which in certain areas, is about 3mm thick. This area is best handled with the dremel bits.

Last but not

least (and not visible in this shot) there's the roof panel. This is about as thick as Sheffield Steel, use the blade to thin this down.

Takes

a while, but when you persevere...the scale will reward you

|

tamar

|

posted on 13-6-2016 at 17:48 |

@ Gio:

There are two types of lightweight interiors available for a Bentley Continental GT3:

From Slot.it with code S06-XA1 and from MTR32.com (Milan Tomasek)

@ Munter:

Cutting the center section from the roof alone will save you 1,5 - 2,0 gr. The Conti is a big car with big windows and with the Scalex they're the

bullet proof kind wink.gif

@ all concerned, interested

For the GT3 Open class DiSCA wants to use as much parts from the stock cars as possible.

A tray type interior is a prerequisite to fit the O2 chip and AW longcan Motor, so as that needs to be swapped anyway, we might just as well use a

lightweight one.

Stock windows can be trimmed as long as they follow rule 1.2

1.2. The exterior of the body shell must appear original and unmodified from the manufacturers design when placed on the circuit and viewed from angy

angle.

So as long as the visible part of the windows is there....

|

Grunz

|

posted on 13-6-2016 at 16:04 |

Given that I am preparing a similar car, thanks Gary for sharing the details.

Anyway, I am stuck at the moment without the interior.

|

LMP

|

posted on 12-6-2016 at 19:07 |

Well, this isn't quite as good as one of Tamar's posts but I thought I'd make my contribution

These techniques are likely to be applicable to a number of Scalextric or Carrera shells with potential for use in GT3 racing. In particular this is

relevant to the DiSCA GT3 Euroseries regulations as all of the mods here are allowed within those regulations.

The finished shell will of course require a polycarbonate interior with driver's head, bust, seat back and steering wheel.

Currently my Bentley body tips the scale at 19.2g, adding ~1.5g for the interior I should come in at less than 21.0g. That's still less than the

factory issue bare shell by Scalextric, so there are gains to be had!

You could of course go to town, but the gains made vs. risk of fragility are not worth it in my opinion. I'm satisfied that this shell will be

competitive on a grid requiring a 19.0g minimum body mass, so let's see how it goes in Manchester!

|